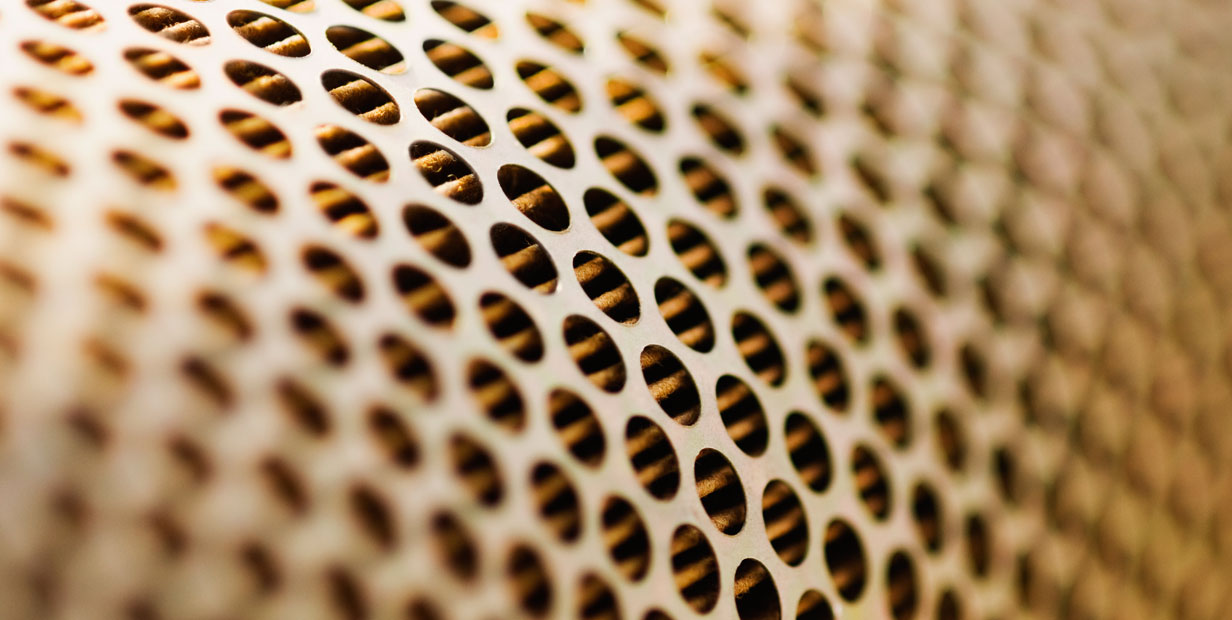

- Torn pleat material

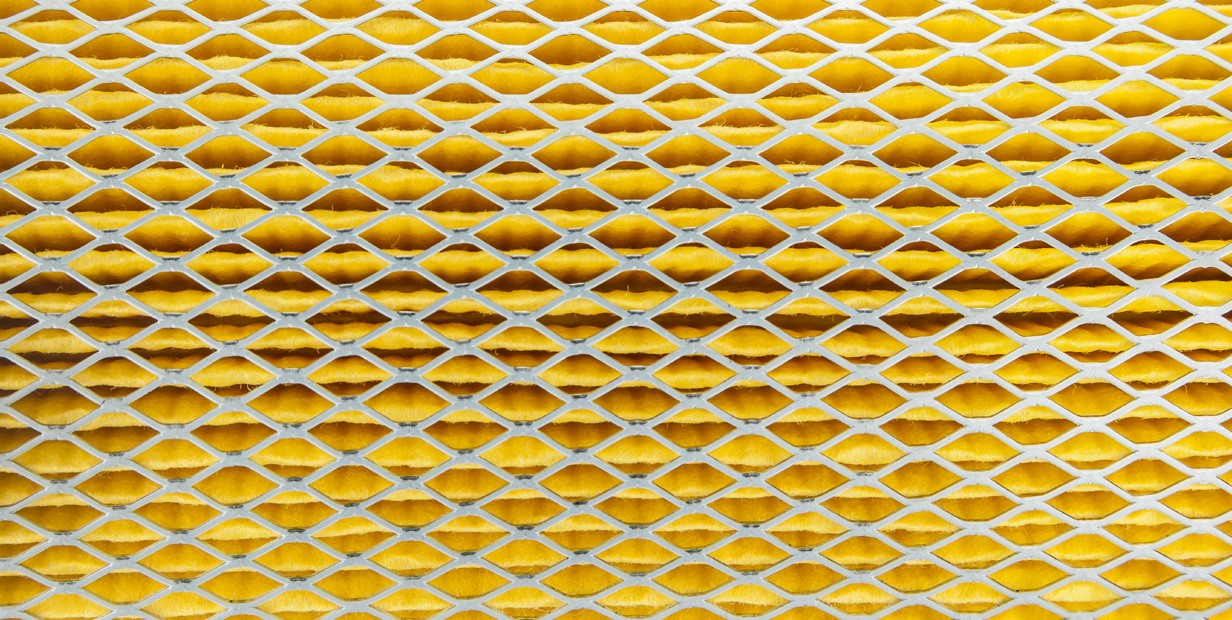

- Damaged internal or external cage

- Missing gasket material

- Missing endcaps

THE FILTER CLEANING PROCESS

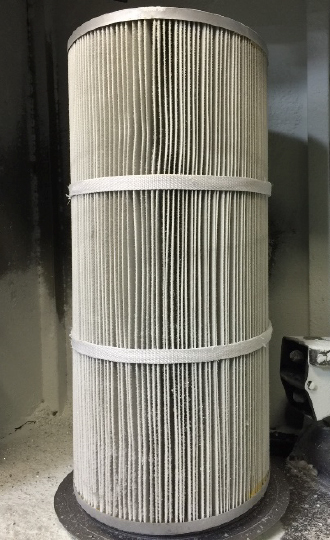

Pre-cleaning inspection

When we receive the filter into our building we first do a physical inspection. What we look for at this point is any obvious damage to the filter such as:

Dry Cleaning

To help ensure the filter get as clean as possible and to help increase filter life, We run each filter in our Dry cleaning apparatus designed by Sonic Dry Cleaning.

A low power air line blows through nozzles pointed strategically at the filter to ensure as much of the contaminant is removed as possible

This is only used as a pre-cleaning method and it helps to remove most of the surface contaminant

Wet Cleaning

After the dry cleaning cycle is complete, the filter will be wet washed in our washer designed by the Wix Filter Corporation or our specially designed filter washing machine. This is a safe way to remove the remaining deep particulate that was not able to be removed through dry cleaning.

We use a non invasive degreaser soap with the water to help break down the tougher dirt.

Once checked for any remaining particulate, the filter is flushed inside-out to ensure all remaining contaminant is flushed away from the pleats.

Spinning/drying

After the filter has been washed, we spin the filter to remove excess water. This removes most of the excess water and prevents swelling of the pleats. Next it goes into a dryer preset to 125 degrees. This is hot enough to dry the filter but not enough to damage it.

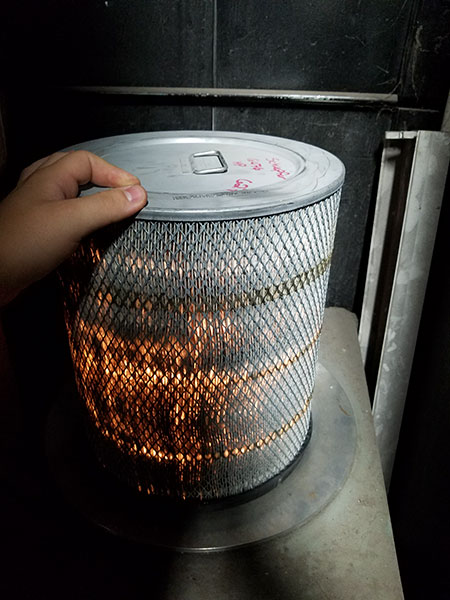

Post cleaning inspection

After the filter has be thoroughly dried, the filter is visually inspected again for any damage. Once it passes, it goes into a dark room where a light is shined through it to ensure no pleats have been torn and no seams have been broken. Any gaskets that have been removed will be repaired or replaced at this point and all damage (dents) will be fixed as well.

Restriction

Next the filter goes back on the manometer to check the air flow restriction again. At this point the filter will meet or exceed the air flow restriction from when it was a new filter. We keep a list of restriction readings of new filters for all filters we clean. The restriction is recorded on the filter and kept for your records.

Boxing/shipping

Once the filter has completed all the steps in the cleaning process, it is visually checked one final time for damage/any problems. It is then boxed in a new clean box.

We include your company information as well as a part number and a date cleaned on our reconditioned filter from Michigan Filter label. By request, any other information can be added.

Boxes are stacked on pallets and shipped direct back to your location either by our delivery trucks or by a third party carrier.

Copyright 2016. All rights reserved.